The 2D-Shuttle is the most advanced and efficient shuttle that Logiqs has ever made.

The 2D-Shuttle is a unique greenhouse automation solution, which is designed and built by Logiqs. This system is unmatched in its modular design, that allows for a flexible and scalable system.

At the core of the system stand two components: the 2D-Shuttle and the A-Track Transport Line.

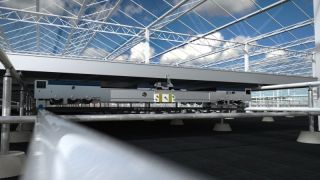

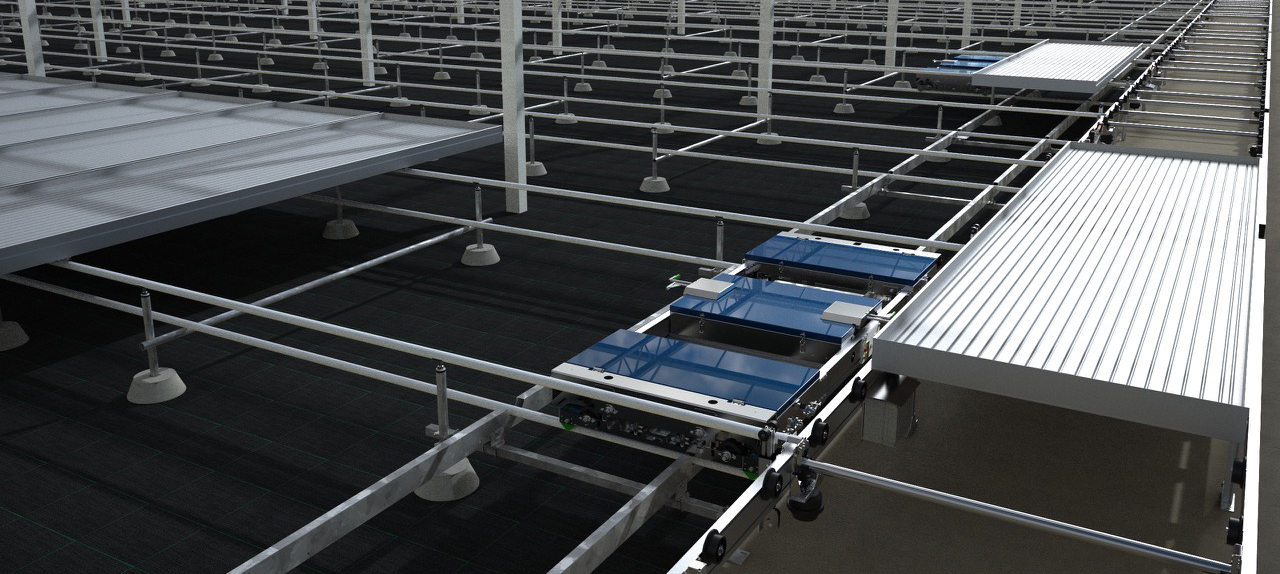

The 2D-Shuttle is a semi-autonomous vehicle that rides underneath the rolling benches, using the heating pipes as rails.

Using it’s grabbing mechanisms and sensors the 2D-Shuttle can move the individual rolling benches conforming to the transport tasks assigned by the grower using the Dat-A-Control Software.

The 2D-Shuttle can also switch rows independent of other machines.

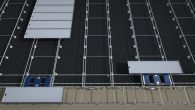

The A-Track transport lines ensure bench movements between rows and connects the growing area to the work area.

Each individual A-Track Transport Line section is powered by just one drive unit, using two speeds: a fast one for normal bench movements and a slow one for precise positioning of the bench on the lifting frame.

The A-Track Transport Line has been used by growers worldwide for the last 20 years. Its design has evolved and matured, becoming the industry standard, due to its durability and high capacity.

In order to be able to move between rows, the 2D-Shuttle makes use of a X-Rail which usually spans the whole length of the growing area.

The X-Rail is designed using standardized parts, helping keep the initial deployment costs for the 2D-Shuttle system low.

Depending on the required capacity, one 2D-Shuttle can fully automate up to 2 hectares of growing surface. The number of transport line sections depends on the length of the Transport Line.

Unmatched flexibility:

Transport task using a single 2D-Shuttle

When the system uses one 2D-Shuttle, the 2D-Shuttle first pulls the bench from the row and passes it on to the Transport line.

Once the bench is on the transport line, the 2D-Shuttle switches to the X-Rail, and follows the table to the destination row.

The 2D-Shuttle then pulls the bench from the transport line into the destination row. The 2D-Shuttle can now move on to other tasks.

Transport task using a couple of 2D-Shuttles

When using a couple of 2D-Shuttles, the task is divided with one 2D-Shuttle pushing benches onto the transport line.

The other 2D-Shuttle then pulls the benches into the destination row. This allows the first shuttle to continue pushing benches from the first row.

Our software controls the system and makes sure the tasks get completed in the most efficient way and without the 2D-Shuttles getting in each other's way.

Scalable in size and capacity:

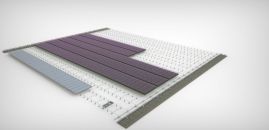

The ideal system for phased construction, in both hardware and software. Adding extra growing surface and connecting it to the existing system is done at a fraction of the cost, compared to conventional automation solutions. If capacity requirements grow, extra 2D-Shuttles can be added to the system without requiring any major modifications.

Modularity

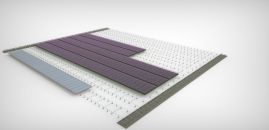

Step by step

Whether it be hardware or software modularity, there is no other system on the market today that can match the 2D-Shuttle system. This modularity makes the 2D-Shuttle system ideal for phased builds. Growers can start off with a manual rolling bench system and manual transport lines. Then automate it in the following phases. This keeps initial costs to a minimum, while at the same time giving the grower instant access to all the benefits of a rolling bench system. Then in following phases the 2D-Shuttles and X-Rails can be added, while the transport lines can be fitted with ADU - Drive units.

The Dat-A-Control software and all its modules can easily be adapted to take phased constructions into account.

Dat-A-Control - The most advanced greenhouse control and registration software available today!

By using Dat-A-Control, the grower gains full control over all the machines and plants in the greenhouse directly from a PC or a smartphone.

Dat-A-Control's efficient transport algorithms ensure the efficient distribution of tasks to all the machines involved in a transport task.